This slideshow requires JavaScript.

Photos of the wax casting process- melting the wax in a saucepan before leaving it to cool to pouring temperature (the wax needs to be cool enough that it coats the side of the pan), then pouring into the secured moulds, including the larger brick mould, before de-moulding and removing excess wax/working the details back in.

Video of two wax casts, fresh from the mould- you can see that there is excess wax that needs to be removed, and some of the details need to be worked back in to the casts.

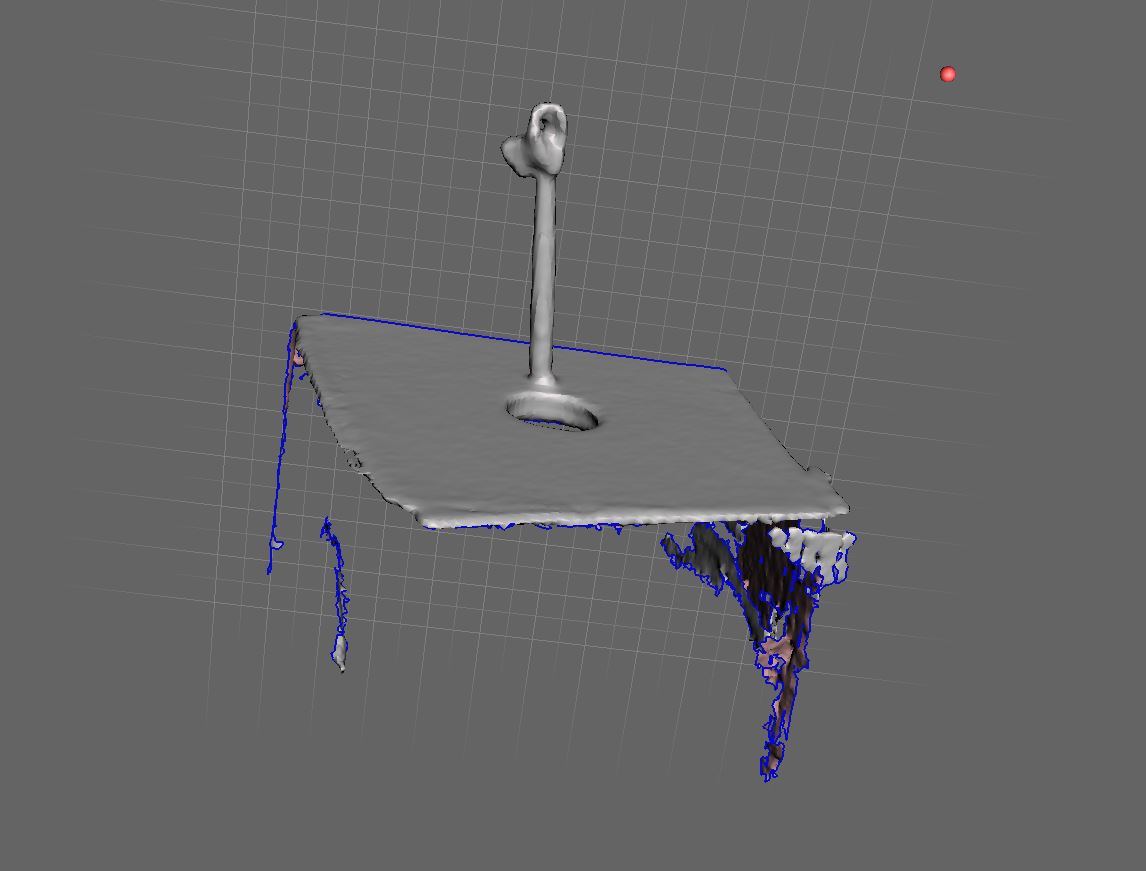

Video made up of a clip showing the second, larger batch, of wax casts fresh from the moulds, followed by a clip of me working on one of these casts to remove excess wax and work a hole back into the cast to mimic the original bone. The final photo is of the wax cast from the previous clip next to the original bone I cast it from- you can see that I have worked some of the details lost during the hot rubber mould process back into the wax cast.

The two clips in this video show the first hollow wax cast of the brick I found on the river, and the second cast next to the original brick- you can see how the hot rubber mould picked up most of the detail from the brick, and how that has translated to the wax casts. You might notice some lines on the casts- this is because to make a hollow cast you need to pour in the wax slowly and roll the mould gently around to ensure the wax coats the mould properly- I did this too slowly so there are lines visible. Next time I use the mould I will be careful to pour the wax faster to avoid this happening- I may melt these two casts down and redo them. The brick casts need to be hollow as to make a solid bronze of that size would be too costly, and too heavy. I will either have to leave the hole in the bottom, or weld a small piece of metal over the hole, but this is something I will tackle when I get to that stage.

Unfortunately this was all I was able to get done before the workshops closed for the break, but I am looking forward to getting back into the foundry/plaster room and continuing my work! The plan is to make at least two of each bone in wax, and then make at 2 – 4 large moulds to go into the kiln and then be poured, as I want a copy of each bone in aluminium and in bronze. I have also been shown a material called glass wax, which is used in the film industry to make objects that mimic glass, and if I can afford it I would like to experiment with this medium as well, as it will give me another material and colour to analyse.