(I took this photo before I swapped out the keyboard and mouse for the cleaner ones)

Overall I am surprisingly really happy with how my installation turned out- the room is a really good, well lit space, with large windows, and it looks much better since I painted it, and swept and mopped it. I am also really pleased I was able to make the table top for free from scrap wood, as that saved me a lot of money, and I think it looks much better than the Ikea table tops do anyway. I decided to keep the trestle legs I got from the BA student black, as I liked the contrast (and also I’m lazy and painting over black paint with white would have been a nightmare) and I think it helps to break up all the white in the room. I had to ask my classmates to tell me the river Thames I painted into the table top looked fine, because otherwise I never would have stopped trying to touch it up and make it “perfect”. Considering I didn’t use masking tape or anything except the pencil outline and paint I think it came out well, and is fairly recognizable for what it is, without any need for labels or a more literal representation.

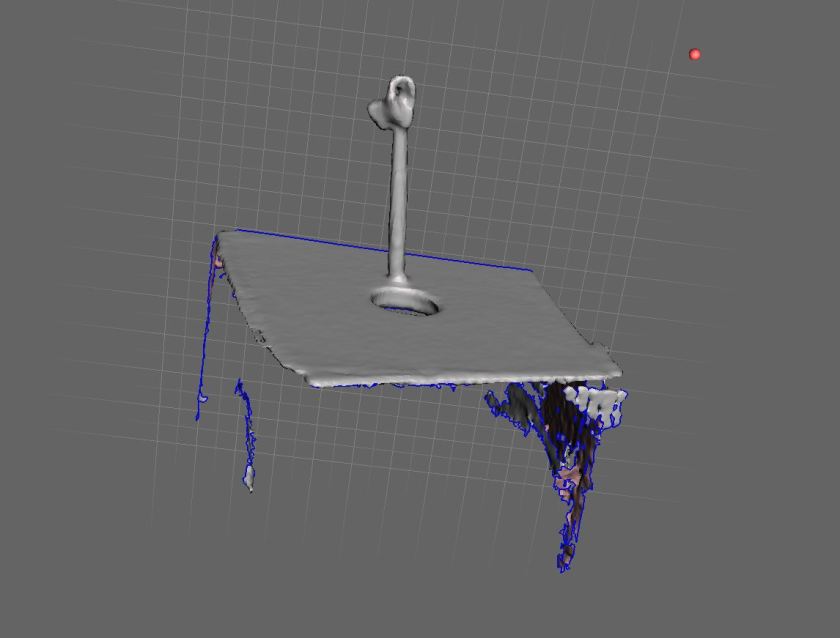

In terms of curating the objects for the exhibition I feel that I have chosen the right amount, and the right selection of materials- I was not able to get the aluminum pieces to a high enough standard, so they have been omitted, the other lot of glass wax pieces I made came out much less transparent and much milkier looking (due to the touch of blue wax I added to offset the yellowing that had happened from the glass wax being overheated) so I left those out and put in the first lot I made, which are much clearer and more transparent. I also left out the herculite casts as they were not up to standard, and are also still fairly fragile compared to the other materials, and I left out the iPad 3D prints, as the Einscan ones were of much higher quality.

In terms of the digital work on screen I am very happy with how it looks- I have chosen one of the larger bones that has a particularly interesting form for the audience to play with, and I feel that Meshmixer was a good choice of programme for the audience to use, as it is fairly simple programme to mess around on- hopefully people will use it and enjoy playing around! I made a 2 minute video, which is on one of my earlier posts, which shows how to move around the 3D model, how to zoom in and out, and some of the basic tools they can use on Meshmixer, in case anyone gets stuck, and this is on the Mac desktop, titled “How to Use”.

I have discussed this previously, but I chose the five bones that I did as the jaw bone pieces proved difficult to cast in some of the methods, so much so that I could not get a good cast of them in the herculite, or glass wax, so I decided not to include them at all. Also they are a bit less ambiguous than the other bones, so I felt it best to leave them out, as I like the ambiguity of the shapes of the other bones. Also I left out the brick, despite having cast it in herculite, glass wax, bronze, and aluminum, as I felt it looks odd to have 5 bones and then the brick by itself. This is a shame, as the casts of it are quite beautiful, but it would have stood out too much, so it was necessary.

when I think back I thought I would have recreated the rope, brick, plastic bottle, and driftwood in different materials like I did originally with the vacuum forming, for the final show. Unfortunately the rope and bottle became unusable after the vacuum forming, and the driftwood turned out to be quite complex to cast, so I never ended up doing it. The bones became my focal point quite by accident, as I found myself drawn to the shapes and textures of them when I first started experimenting with the macro lens back in the first term. I don’t regret this, because I feel like I have made a strong body of work, that I am very proud of.